Introduction:

At present, there is no concept of servo intermittent valve in Japan and South Korea. The introduction of domestic servo intermittent valve is an important embodiment of independent research and development of domestic lithium battery coater equipment, and is one of the technical highlights that surpass Japan and South Korea's lithium battery coater equipment.

With the development of extrusion coater technology, the market penetration rate of domestic extrusion coater is also rising step by step. In terms of the types of coating machines purchased in the first half of 2015, the market share of extrusion coating machines has reached 70%, especially for large and medium-sized lithium battery enterprises and newly established power battery manufacturers, almost all of them use extrusion coating machines.

[text / Wang Zhengtang] since the beginning of the localization of extrusion coating, the development of extrusion coater technology in China has made great progress, and has a great momentum to catch up with and surpass the equipment manufacturing enterprises in Japan and South Korea.

With the development of extrusion coater technology, the market penetration rate of domestic extrusion coater is also rising step by step. In terms of the types of coating machines purchased in the first half of 2015, the market share of extrusion coating machines has reached 70%, especially for large and medium-sized lithium battery enterprises and newly established power battery manufacturers, almost all of them use extrusion coating machines.

One of the core components of extrusion coater is intermittent control valve. The intermittent coating function of extrusion coater is completely realized by the control of intermittent valve, and the dimensional accuracy and longitudinal consistency of coating thickness of intermittent coating are also guaranteed by the control and adjustment accuracy of intermittent valve.

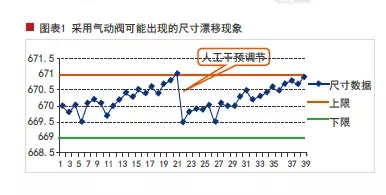

At present, pneumatic control valve is used at home and abroad, which has the advantages of low cost, simple maintenance and control. However, due to the low speed accuracy of the cylinder, it is easy to be interfered by external factors, such as the change of air pressure and the friction of the sealing ring, which will affect the opening and closing speed of the intermittent valve, resulting in the size drift of the intermittent coating (as shown in Figure 1) and the unstable thickness deviation of the coating head and tail.

Introduction:

At present, there is no concept of servo intermittent valve in Japan and South Korea. The introduction of domestic servo intermittent valve is an important embodiment of independent research and development of domestic lithium battery coater equipment, and is one of the technical highlights that surpass Japan and South Korea's lithium battery coater equipment.

With the development of extrusion coater technology, the market penetration rate of domestic extrusion coater is also rising step by step. In terms of the types of coating machines purchased in the first half of 2015, the market share of extrusion coating machines has reached 70%, especially for large and medium-sized lithium battery enterprises and newly established power battery manufacturers, almost all of them use extrusion coating machines.

[text / Wang Zhengtang] since the beginning of the localization of extrusion coating, the development of extrusion coater technology in China has made great progress, and has a great momentum to catch up with and surpass the equipment manufacturing enterprises in Japan and South Korea.

With the development of extrusion coater technology, the market penetration rate of domestic extrusion coater is also rising step by step. In terms of the types of coating machines purchased in the first half of 2015, the market share of extrusion coating machines has reached 70%, especially for large and medium-sized lithium battery enterprises and newly established power battery manufacturers, almost all of them use extrusion coating machines.

One of the core components of extrusion coater is intermittent control valve. The intermittent coating function of extrusion coater is completely realized by the control of intermittent valve, and the dimensional accuracy and longitudinal consistency of coating thickness of intermittent coating are also guaranteed by the control and adjustment accuracy of intermittent valve.

At present, pneumatic control valve is used at home and abroad, which has the advantages of low cost, simple maintenance and control. However, due to the low speed accuracy of the cylinder, it is easy to be interfered by external factors, such as the change of air pressure and the friction of the sealing ring, which will affect the opening and closing speed of the intermittent valve, resulting in the size drift of the intermittent coating (as shown in Figure 1) and the unstable thickness deviation of the coating head and tail.

Figure 2 size distribution of coating with servo intermittent valve

2. It can realize man-machine interface control, adjust parameters, and improve the automation degree of intermittent valve. For the method of batch coating head and tail thickness adjustment, the running speed and action time sequence of servo motor can be directly modified on the touch screen, and the parameters can be quantified. Therefore, the operation reference file can be formed, which has strong repeatability and operability, and reduces the dependence on human experience.

3. The service life of servo motor is longer than that of cylinder. Although the coating condition is not good, and the servo motor can be used for at least 5 years, the service life of the cylinder is less than 1 year under the condition of frequent and high-pressure movement.

Compared with pneumatic intermittent valve, servo intermittent valve has obvious advantages in improving the accuracy of coating products. In the future, it will be widely used in extrusion coater equipment. It is the innovation of core technology of extrusion coater, and will bring a milestone in improving the accuracy of lithium-ion battery coating and the automation and intelligence of coating equipment.