What are the precautions in the working process of coater?

Matters needing attention in working process of coater

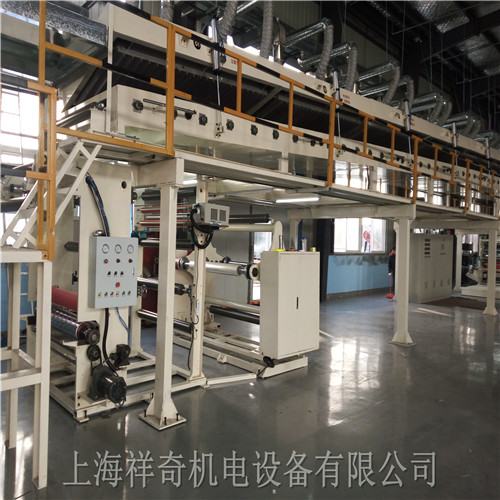

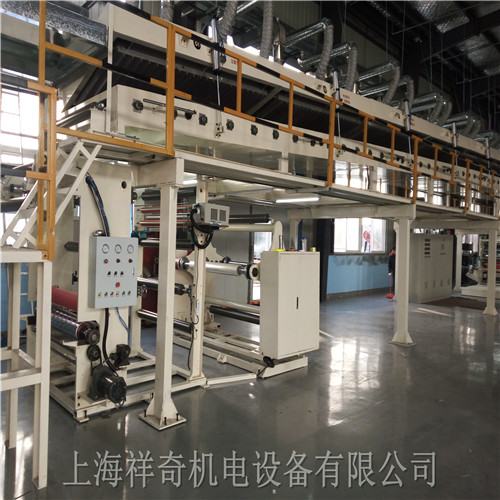

Coater is used for BOPP sealing adhesive tape coating production. The rolled base material is coated with a layer of glue, paint or ink for specific functions, and then dried before winding. It uses a special high-speed coating head, which can reduce the occurrence of bubbles. The take-up and take-off of the coater are equipped with full speed automatic film organization, tension closed-loop automatic control.

Coater in the process of operation, the first will follow two operation process.

1. Thickness determination process of forward roll

2. Reverse roll coating handling process.

Coating machine reverse roll coating and coating window: in the polar cloth machine, the slurry coating on the coating roll is transported to the copper foil or aluminum foil wrapped on the back roll in the opposite direction in the bright roll vacancy area. Therefore, the coating process is also necessary to meet the rules of reverse stick coating. In the process of reverse roll coating, if the vacancy of two rolls is small and the capillary number is low enough, that is to say, in the case of low viscosity or speed, the activity in a wide speed ratio plan is relatively stable. Good coating quality can be obtained. If the vacancy is relatively large, when the coating speed is high, there will be air entrapment and many fine bubbles on the coating surface. Sometimes in order to increase the output value, choose the coating speed, can present the harm of air entrapment, in order to eliminate this harm, choose the operation method of reducing the vacancy. Too small space, so that the coating roll and back roll knead each other, add additional motor and reducer load, constitute abnormal wear. This is the second reason why the coating speed of the reverse roll is limited

Spin roll coating and its coating window: first, introduce the term coating window in coating skills. Any coating method (method) has an applicable plan. It can carry out coating in a harmless place within certain operating conditions (plan), that is, evenly coating the thin fluid layer on the support. This coating operation plan is called coating window in coating skills. In the coater, it is controlled by adjusting the metering vacancy between the coating roll and the metering roll with the same change direction in the forward roll coating, and the coating with the required thickness is formed on the coating roll. Coating method is a special way to roll, that is, a measuring roll does not change, that is, the speed is zero, the cross section of the measuring roll is made into a comma shape, also known as a comma scraper. The coating thickness can be adjusted by changing the interval between the scraper and the coating roller. In this special forward roll coating method, improper operation, knife edge orientation against the operation orientation, coating parameters and slurry parameters are not in a certain plan, can present the harm of vertical channel, known as vertical channel.