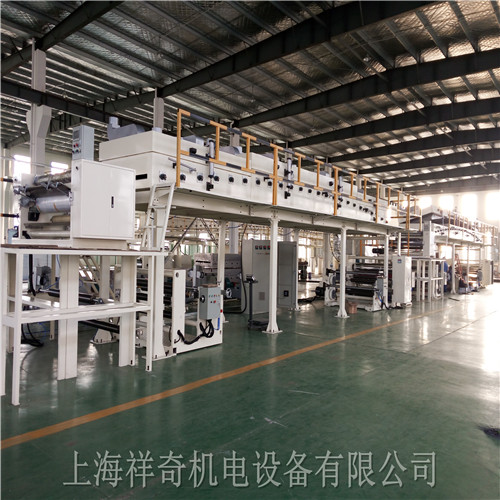

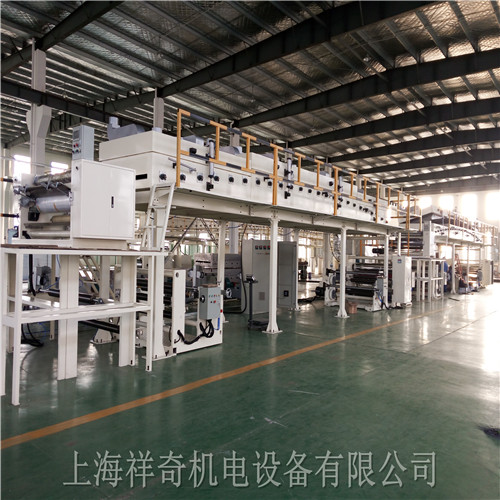

Technological requirements of coater

It is suitable for gluing of shoe material, electronic industry, sponge, EVA, PE, cloth, etc.

Tension system 1. Process requirements

The coating machine needs to glue or ink materials uniformly adhered on the surface of aluminum foil, plastic film or cloth textiles, which requires higher coating process. It not only requires uniform coating height, but also can achieve high-speed non-stop roll change to improve production efficiency.

2. Advantages of the scheme

The tension control at all levels is completed by the frequency converter, and the tension control is realized by the tension sensor. The system is simple and stable. PLC or synchronous controller is used to control the speed of drive roller frequency converter, and it is also used as the linear speed signal of other frequency converters.

S350 closed loop tension control (inductive vector control) can easily achieve constant tension during acceleration and deceleration, save space for installing tension roller, reduce mechanical cost, and ensure uniform coating effect with high precision control. The dual position take-up and take-off reel has pre drive function, which can meet the requirements of high-speed automatic roll change without stopping machine and improve production efficiency. At the same time, accurate coiling control can avoid the bad coiling of vegetable heart type and make the coiling effect better.